Propose the most suitable automatic system to match customs’ needs.

AUTOMATION

KMP LINE

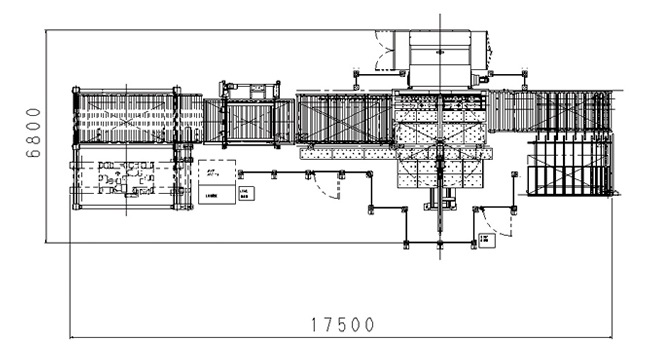

Realize person saving and unmanned system, support the improvement of customs’ production line flexibility. The machines can be used to construct an integrated factory automation line with a loading device and an automatic warehousing.

Person saving, well cost performance, high productivity

ST (setting table) + KMP+PT (unloading tilt table) type

By setting the next metal sheet on setting table during the first metal sheet being bended and storing two products on unloading tilt table, the productivity is increased.

- Material origin set will be performed automatically if you put the material on setting table.

- After that, KMP start to bend.

- Another metal sheet can be set on the setting table during KMP bending the first one.

- After finish bending, the product will be carried out onto unloading tilt table.

- The line can contain 5 workpieces on it (regarding to the product size, it may become 4 workpieces).

Loading device + Inverting machine + ST (setting table) + KMP + PT (unloading tilt table)

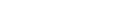

Layout

If there are several pieces of material on loading machine, the only thing you need to do is taking out the products from unloading tilt table by using this full automatic line. It makes automatic person-saving to become reality.

-

Loading device

- Loading device is used to attract accumulated metal sheet and send it to the next step.

- Specification: 1-station type and 2-station

-

Inverting machine

- Inverting machine is used to turn a metal sheet upside down when the metal sheet has burrs on its downside after turret punch or other previous process.

-

PT (unloading tilt table)

- The device is used to transporting the bended products to a suitable place for taking out.

- * Custom-made machine service for your expected specification is also provided.

- * It is subject to change the content and dimensions of specifications for machine improvement without any inform.

- If there is any unclear about our products, please contact us.

Head Office・Factory

TEL+81-766-63-3805

Monday through Friday 8:30~17:00