KMP series

KMP25

A best-selling model built

for productivity.

The KMP25 is a trusted,

It comes in two configurations to suit your application needs.

KMP Return Type

Ideal for single-operator use. Simply place the workpiece on the RT table positioned at the front for smooth, efficient bending. Achieves both labor savings and enhanced productivity.

KMP25 Straight Type

Compatible with automated production lines, this model can be connected to peripheral devices such as automatic sheet loaders and NCT machines. It supports advanced automation and seamless integration across a wide range of production environments.

Two types are available to accommodate different maximum sheet thicknesses: MAX 2.3t and MAX 3.2t. Designed to flexibly meet a variety of processing needs, the KMP25 also incorporates maintenance-free components and offers instant startup with the flip of a switch, no warm-up required. This minimizes downtime and boosts operational efficiency even further.

RETURN

Be able to be operated by only one worker. Make “High productivity” and “Person saving” reality.

RETURN

HIGH PRODUCTIVITY

Pursue well cost performance basing on operating time shortening.

HIGH PRODUCTIVITY

FLEXIBLITY

Be used to construct production line which is suitable for high-variety and small-lot production.

FLEXIBLITY

HIGH PERFORMANCE

Several complex shapes such as R-bending, hemming bending, closing and part-bending, which could not be bent by traditional machines, could be bent by this machine without die exchanging.

HIGH PERFORMANCE

HIGH-PRECISION

AC servo motor driven makes it easy to be correction and processing ability in high precision is demonstrated.

HIGH-PRECISION

ECOLOGY

Support energy saving by using AC servo motor instead of hydraulic.

ECOLOGY

AUTOMATIC

Automatic top-die change device and other mechanism bring automation and support production system.

AUTOMATIC

EASY

Self-developed program is easy to be used. The machine could calculate and process automatic after data input from touch panel.

EASY

General Specifications

- Applicable Work Size

- 〜2500mm

- Applicable material

- SPCC max2.3t SUS430 max1.5t

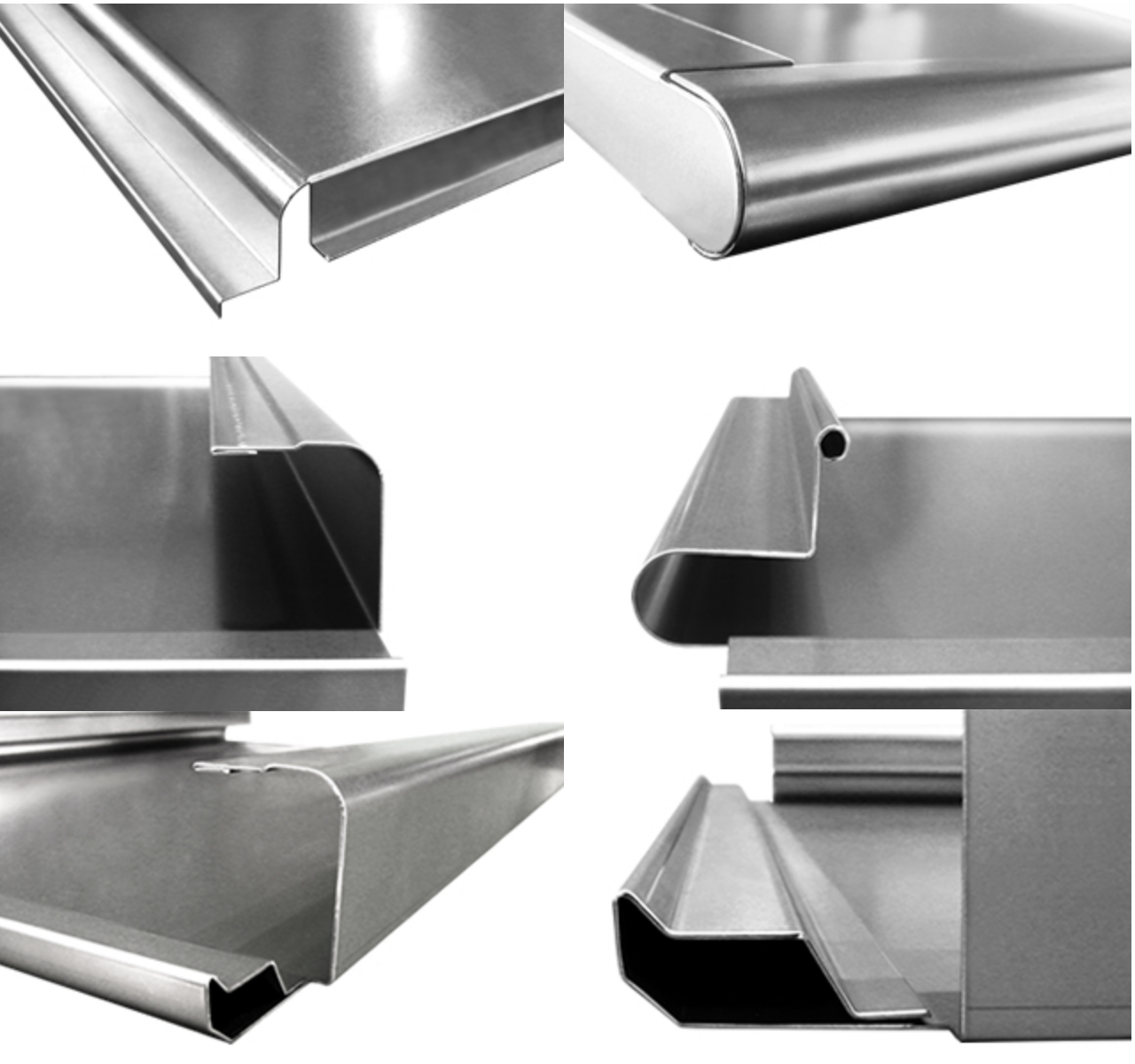

Bending Sample

"The samples above are only a part of our applicable bending shapes.

Information about special bending shapes, please contact us for detail discussion.

Please feel free to contact us."

Contact Us

For product inquiries, quotes, requests, etc.,

please contact us here

Head Office / Technical Center / Factory

TEL0766-63-3805(代)

Tokyo Branch

TEL03-6712-9207

Reception hours: 8:30-17:30

(excluding Saturdays, Sundays, and holidays)

Office・Factory

Head Office & Factory

795 Kasuga, Tode, Takaoka, Toyama, Japan

TEL 0766-63-3805(代)

FAX 0766-63-3804

Technical Center / 2nd & 3rd Factories

496 Ooshimizu, Tode, Takaoka, Toyama, Japan

Tokyo Branch

Tokyo Branch Office: 7F Shinagawa Grand Central Tower, 2-16-4 Konan, Minato-ku, Tokyo, Japan

TEL 03-6712-9207

FAX 03-6712-9208